Browning Manufacturing in Maysville (formerly Ohio Valley Pulley Works) was a family-run business established in 1911 by Edward Parry Browning, LeWright Browning, and Edward’s nephew Samuel Pearce Browning.

In 1886 M. K. “Otto” Sprinkle launched a company in Wheeling, W.Va., that produced split wood pulleys. By 1895 Sprinkle’s company was failing (due to lack of hardwood around Wheeling), so, taking his machinery along with him, he boarded a steamboat bound for Cincinnati in search of better opportunities. While stopping overnight in Maysville, Ky., Sprinkle met with local businessmen, one of whom was Edward Parry Browning. These businessmen, when they learned Sprinkle’s intention to begin a pulley manufacturing company in Cincinnati, convinced Sprinkle that he should open his business in Maysville instead. Sprinkle agreed, the businessmen became investors, and the Ohio Valley Pulley Works was born; the new firm was incorporated in 1896.

The Ohio Valley Pulley Works produced split pulley for use on line shafts that held flat leather belts connected to smaller pulleys. The pulley rotation and movement of the belts transmitted power to the machines. Known unofficially as the Pulley Works, the company earned $15,626 in 1897 and continued to grow despite numerous difficulties facing it. On July 2, 1899, a fire in the plant destroyed almost everything and nearly forced the investors into bankruptcy. The owners agreed to rebuild, and that year the company reported $45,861 in earnings, even though it had closed for three months to rebuild.

After the fire, the Pulley Works continued to manufacture wooden pulleys while competitors were using new technology to develop steel pulleys. Seeing the potential in this new steel product, the investors secured a contract with the Oneida Steel Company in 1911. According to their contract, the Ohio Valley Pulley Works would sell the steel pulleys made by the Oneida Steel Companythroughout the territory south of the Ohio River and west of the Mississippi River. Added income from this contract allowed the pulley company to continue expanding. On December 29, 1911, Edward Parry Browning, nephew Samuel Pearce Browning, and Le Wright Browning bought out the other shareholders of the Pulley Works and changed the company’s incorporation, converting it to a family-run business.

In 1918 the Oneida Steel Company refused to renew the contract, leaving the Pulley Works without any means to market steel pulleys. The Pulley Works filed suit and lost. At this point, the family was uncertain how to save this portion of their business. During this time, the limestone wooden pulley, a new version of the original pulley system, had been created. This newly designed wooden pulley was the salvation of the company.

In 1936, the Browning family reacquired the Maysville operations—essentially a leveraged buyout of General Fibre Products’ local business. They rebranded it as Browning Manufacturing Company on July 1, 1936.

A year later, in 1937, operations were disrupted by a devastating flood that forced a temporary shutdown of the East Second Street plant; machinery was relocated, and offices were moved to a family residence for continuity

The Great Depression of the 1930s hit Mason Co. as severely as the rest of the country. Nonetheless, the Browning family, who now owned the Pulley Works, were able to keep their workers employed, and the company’s high volume of sales of its limestone wooden pulleys during World War II (1941–1945) helped the company to prosper and continue to grow.

Over the years, Browning continued to expand the technologies it offered the market.

- Initially, its wooden pulleys were used by customers who had one power source for their entire plant. (Water wheel or Steam Engine)

- As farmers transitioned from horses to internal combustion, Browning developed the paper pulley to connect a tractor to the farmer’s driven machines. (Saws, feed mills etc.)

- Browning was an early V-Belt sheaves provider as individual electric motors began to drive each machine in a factory.

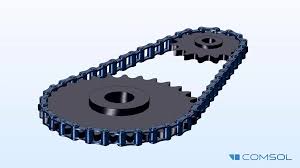

- Roller Chain was the next product Browning started to manufacture.

- Now innovation started to accelerate as mounted bearings and open gearing were added.

- Enclosed worm gearing arrived soon after Emerson Electric took ownership. From then on, the product lines offered continued to expand at an increasingly fast rate.

The Pulley Works continued to succeed. In 1969, under the direction of Edward Parry Browning’s grandnephew John Nelson Browning and three great-grandnephews–Robert E. Browning, Louis Nulton Browning, and Laurance Le Wright Browning Jr., this family-owned business, which started in Maysville in 1897, was sold to Emerson Electric of St. Louis MO. For several years it operated as Browning Manufacturing Division of Emerson Electric. In the mid 1980s Emerson Electric merged its Browning, Morse divisions to form the core of Power Transmission. In 2014 Emerson sold its Emerson Power Transmission division to Regal Beloit Corporation. As 2020 ends, Emerson and Regal are in the process of divesting all their remaining industrial property in Mason County KY.

Comer, Elizabeth. “The Brownings: An Unwavering Maysville Family.”NKH 11, no.2(Spring-Summer 2004): 21–27.

Comer, Martha. “Browning Family influence Felt throughout Maysville,” Maysville Ledger Independent, August 18, 1986, 10.

Mason Co. Deed Book 96, 1896, p.458; Book 114, 1911, p. 367.

Elizabeth Comer Williams